Master Engineering offers comprehensive pneumatic system designs with services customized to meet your specific requirements. From simple compressed airlines for assembly workstations to highly intricate turnkey designs for industrial process equipment, we cover a wide spectrum. We collaborate closely with you to grasp your needs and formulate tailored solutions that optimize performance, efficiency, and safety.

Whether you're seeking a fundamental system setup or a sophisticated high-pressure pneumatic system, we possess the knowledge, experience, and resources to deliver dependable and cost-effective designs. From meticulously selecting components and sourcing to seamlessly integrating systems and providing documentation, we offer end-to-end services to ensure smooth implementation and sustained support for all your pneumatic system needs.

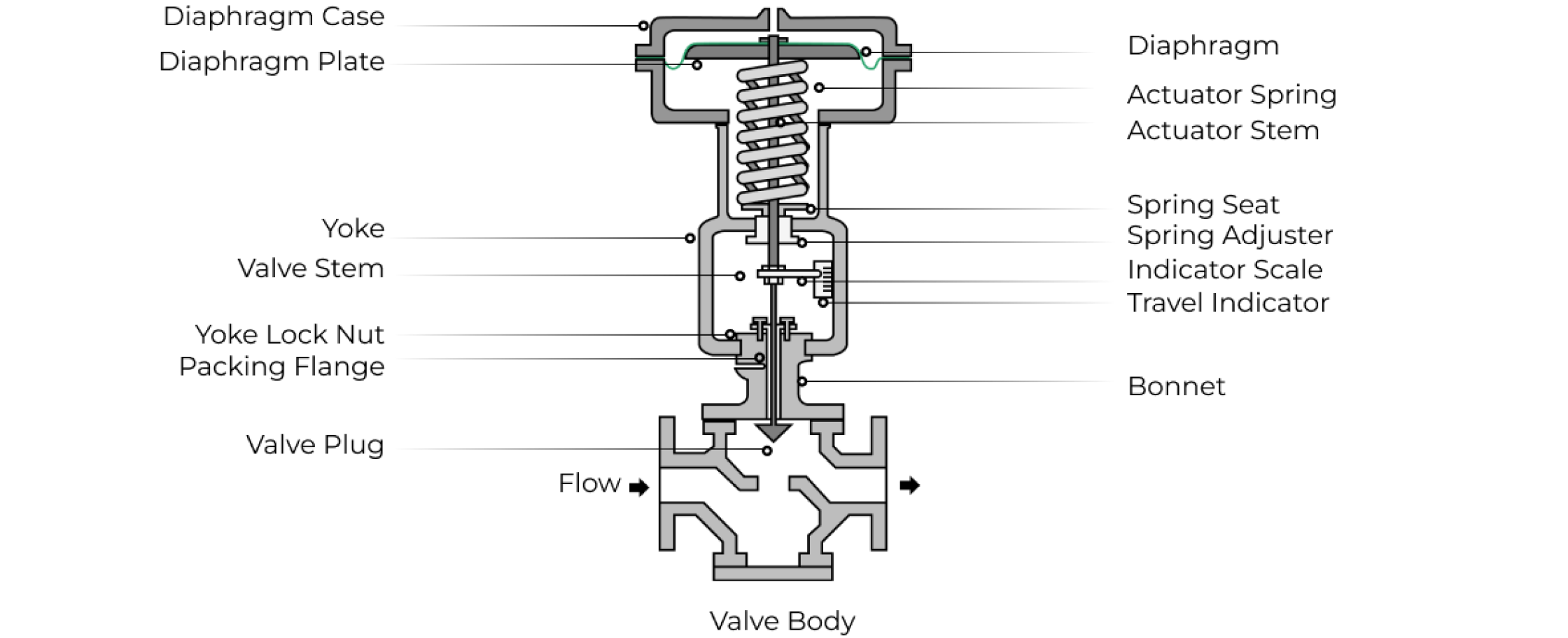

Control Valve Parts

In power generation and distribution facilities, pneumatic actuators find application in controlling valve operations within steam or gas turbines, guaranteeing optimal power generation efficiency. Pneumatic systems also find use in controlling valves that regulate fluid flow and pressure within electrical substations and power distribution networks.

Pneumatic systems find utility in transporting waste from various collection points to central transfer stations. Vacuum-based systems equipped with pneumatic tubes offer an efficient means to convey waste across extended distances, diminishing the necessity for manual handling and enhancing waste transfer logistics.

Pneumatic systems play a pivotal role in various drilling operations, including blast hole drilling, exploration drilling, and core sampling. Renowned for their lightweight design, portability, and high power-to-weight ratio, pneumatic drills offer notable advantages.

Pneumatic actuators and valves find application in regulating the movement and positioning of drilling equipment such as clamps, chucks, and feed mechanisms. This integration augments precision, reliability, and safety throughout the drilling process.

Pneumatic Autofeed Drilling Machine

Case Study

Air Dynamics partnered with Evergreen to enhance the performance and operational reliability of their pneumatic conveying system, a critical component for efficient bulk material transfer within their production facility. Through comprehensive system analysis, Air Dynamics engineered a customized solution focusing on airflow optimization, pressure loss reduction, and mitigation of material degradation during transport. The retrofit included precise calibration of air velocity and pipeline configuration, resulting in improved conveying efficiency, significant energy savings, and reduced downtime. This case exemplifies the value of engineered pneumatic conveying solutions tailored to complex industrial process requirements.

For more technical details, view the full case study here: Air Dynamics Pneumatic Conveying Case Study

350 Hwy 7 E # 307, Richmond Hill, ONL4B3N2,Canada

Monday – Friday 9am to 5pm